Why Overweight Cargo Challenges Demand Expert Solutions

Overweight cargo solutions are essential for businesses shipping heavy machinery, construction equipment, or dense materials that exceed standard weight limits. These solutions include specialized equipment like tri-axle and quad-axle chassis, accurate weight verification systems (VGM), compliant documentation, strategic route planning, and mode-specific expertise across sea, air, road, and rail transport.

Quick Reference: Key Overweight Cargo Solutions

| Challenge | Solution |

|---|---|

| Exceeding Weight Limits | Use tri-axle or quad-axle chassis; split loads across multiple containers |

| Regulatory Compliance | Obtain Verified Gross Mass (VGM); secure special permits; verify BOL accuracy |

| High Costs & Fees | Pre-plan shipments; optimize packaging; choose carriers with heavy-lift expertise |

| Equipment Damage Risk | Use certified restraint devices; employ specialized handling equipment |

| Modal Restrictions | Match cargo to appropriate transport mode; understand sea (30+ tons), road (44+ tons), rail (40,000+ lbs), and air (500+ kg) thresholds |

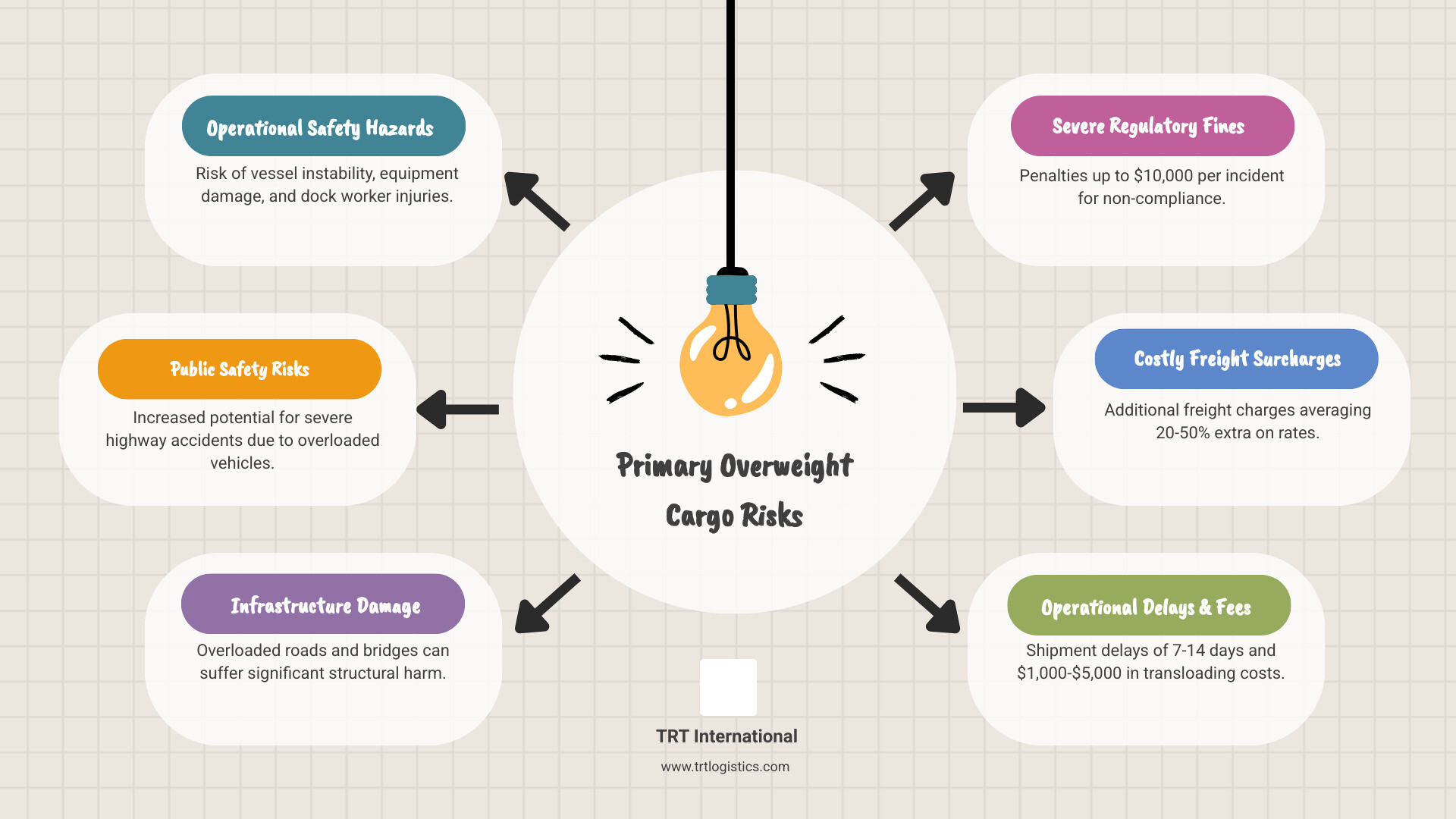

The stakes are high. According to the World Shipping Council, container trade volumes have grown 5% annually over the past five years, yet overweight violations can trigger fines up to $10,000 per incident, delays of 7-14 days, and surcharges averaging 20-50% extra on freight rates. Beyond financial penalties, overweight containers create serious safety risks—from vessel instability and equipment damage to highway accidents and dock worker injuries.

Navigating these challenges requires more than just knowing weight limits. It demands understanding how regulations are evolving for 2026, mastering Verified Gross Mass (VGM) requirements, leveraging specialized equipment, and adapting to mode-specific restrictions—including e-commerce platforms like Amazon FBA, which regularly introduces new weight categories.

1. “Overweight” Isn’t a Single Number: Decoding 2026’s Evolving Limits

When we talk about “overweight cargo,” it’s rarely a simple, universal threshold. The definition itself, and the regulations surrounding it, are dynamic, constantly evolving, and vary dramatically depending on the mode of transport and the specific infrastructure involved. For 2026, we are seeing significant updates and clarifications that underscore the need for precision and adaptability in logistics.

Regulations are always evolving to improve safety, preserve infrastructure, and improve efficiency. While global standards like those from the World Customs Organization (WCO) influence national updates, the implementation often happens at a regional or national level. This means what’s considered overweight for a truck on a highway in New Jersey might be perfectly acceptable for a container ship crossing the Atlantic. Our job is to stay ahead of these changes, ensuring our clients’ shipments are always compliant, no matter the journey.

Road, Rail, Sea, and Air: A Comparative Look

Let’s break down the standard weight limits and 2026 updates across different transportation modes, giving us a clearer picture of what constitutes overweight cargo today:

-

Road Transport: This is where we see some of the most intricate regulations, primarily due to varying state and federal highway laws. In the US, the maximum gross vehicle weight (GVW) for highway transport is generally 80,000 lbs (36,287 kg) for a 5-axle rig. However, the cargo weight within a container is much lower because we must account for the tare weight of the truck, chassis, and container itself.

- For a 20′ container on a triaxle chassis, the cargo capacity can be up to 44,000 lbs (19,958 kg).

- For a 40′ container on a triaxle chassis, the cargo capacity can be up to 44,500 lbs (20,185 kg).

- 2026 Updates: New guidelines state that a TEU (20′ container) weighing above 38,000 lbs now requires special handling in trucking. For a FEU (40′ container), the new limit is 46,000 lbs before additional measures are needed. These updates reflect improvements in vehicle technology and infrastructure considerations, aiming to reduce road damage and improve safety.

-

Rail Transport: Generally, rail carriers offer higher weight capacities than road transport, making them an excellent option for heavy cargo for inland legs, especially to and from our locations in Newark, NJ, and Savannah, GA.

- Historically, a TEU (20′ container) might have a maximum of 40,000 lbs.

- 2026 Updates: We’re seeing significant innovation here. The maximum weight for a TEU (20′ container) in rail transport has increased to 42,000 lbs. Even better, new high-capacity rail cars can now handle loads up to 50,000 lbs, offering more flexibility for exceptionally heavy shipments.

-

Sea Freight: Ocean vessels are designed to carry massive loads, so their weight limits are considerably higher than road or rail. However, the container itself has specific limits, and proper weight distribution is crucial for vessel stability and safety.

- A standard 20′ container can typically handle up to 28 tons (approximately 61,730 lbs) of cargo, with an overweight threshold often considered around 30+ tons.

- A standard 40′ container can typically handle up to 30 tons (approximately 66,138 lbs) of cargo, with an overweight threshold around 32+ tons.

- These limits are primarily dictated by the structural integrity of the container and the safe loading capacity of the vessel and port equipment. For a detailed guide on container weight, we recommend reviewing this Overweight container guide.

-

Air Freight: While air cargo is fast, it has the most stringent weight limitations due to aircraft structural capabilities and fuel efficiency requirements.

- Standard air freight pallets often have an overweight threshold around 500+ kg (1,100 lbs) per pallet. For anything significantly heavier, specialized solutions like cargo aircraft charters are often necessary.

- Air cargo operations require meticulous planning and adherence to strict safety protocols. The FAA provides comprehensive guidance on this, which you can explore in the AC 120-85A Air Cargo Operations document.

Understanding these varied limits is the first step in avoiding costly mistakes. What might be standard for sea freight becomes a complex heavy haul challenge on the road.

2. The Domino Effect of Fines and Fees: The True Cost of Non-Compliance

Shipping overweight cargo isn’t just about moving a heavy item from point A to point B; it’s about navigating a complex web of regulations where missteps can lead to a costly domino effect. The financial implications and hidden costs of non-compliance can quickly erode your profit margins and disrupt your supply chain.

When a container is found to be overweight, the consequences are swift and severe. We’re not just talking about a minor inconvenience. Overweight surcharges alone can average 20-50% extra on freight rates, significantly inflating your shipping budget. Beyond surcharges, direct fines for overweight cargo can reach up to $10,000 per violation in key markets, a penalty that can hit hard, especially for multiple containers.

These costs extend beyond direct fines and surcharges. Imagine your shipment being held at a port or terminal because it exceeds legal weight limits for the next leg of its journey. This often necessitates transloading—moving the cargo from the overweight container into one or more new containers. Transloading costs can range from $1,000 to $5,000, depending on the complexity and location. While your cargo is stuck, detention and demurrage fees rack up, typically around $150 per day, turning a simple delay into a financial headache. These delays aren’t trivial either; they can range from 7-14 days, impacting production schedules, customer satisfaction, and overall project timelines.

Beyond the financial hit, the consequences of non-compliance are serious:

- Safety Risks: Overweight containers can lead to vessels being improperly stowed, potentially causing structural damage to the ship or even loss of containers overboard. On land, they can cause damage to chassis and terminal handling equipment, and, most critically, lead to injuries to dock workers or citations and accidents on highways and railways.

- Infrastructure Damage: Overloaded trucks and trains exert excessive stress on roads, bridges, and rail lines, contributing to wear and tear and potentially leading to accidents.

- Legal Liability: If an accident occurs due to an overweight shipment, the shipper and carriers involved could face significant legal liability for damages, criminal charges, and even shipment seizure.

Proactive planning and understanding the true costs involved are crucial. As we often tell our clients, investing in proper overweight cargo solutions upfront is always more cost-effective than dealing with the fallout of non-compliance. For more on navigating these complex freight challenges, explore our insights on Big Shipments, Bigger Solutions: Navigating Oversized Freight.

3. It’s Your Responsibility: Mastering VGM and Accurate Weight Verification

Here’s a crucial piece of information many shippers overlook: the responsibility for accurately verifying cargo weight ultimately lies with you. This isn’t just a best practice; it’s a regulatory mandate, especially for sea freight. The cornerstone of this responsibility is the Verified Gross Mass (VGM).

The International Maritime Organization (IMO) amended the Safety of Life at Sea Convention (SOLAS) to require, as a condition for loading a packed container onto a ship for export, that the container has a verified weight. This rule became legally effective on July 1, 2016, and it’s a game-changer for maritime safety. The SOLAS Convention mandates that the shipper must provide the VGM in a “shipping document” before the vessel is loaded. The VGM is the total weight of the cargo, including any dunnage and bracing, plus the tare weight of the container itself. Loading a packed container without a VGM is a violation of SOLAS and will result in the container being refused for loading.

So, how do we ensure accurate weight verification and compliance?

- Certified Scales: The most straightforward method is to weigh the packed container using calibrated and certified equipment. This is often done at the origin facility or a designated weighing station before it reaches the port.

- Method 2: Alternatively, shippers can weigh all the cargo items, dunnage, and bracing, then add the container’s tare weight (which is usually marked on the container door). This method requires precise measurement of every component.

- Documentation is Key: Once the VGM is obtained, it must be accurately declared in the shipping instructions or a separate communication. The Bill of Lading (BOL) should also reflect accurate weight information.

If a container arrives at a terminal without a VGM, the shipping line will not load it, and it will likely be rolled to a subsequent sailing, incurring delays and additional costs. This highlights why meticulous weight verification isn’t just about avoiding fines; it’s fundamental to the smooth flow of your supply chain.

Tech-Driven Accuracy: Your Best Bet for Overweight Cargo Solutions

In 2026, technology is an indispensable ally in mastering weight verification and compliance. We’re seeing a push towards digital solutions that minimize human error and provide real-time data, changing how we manage overweight cargo solutions.

- Digital Scales with IoT Integration: Forget manual data entry and potential typos. Modern digital scales integrated with the Internet of Things (IoT) can automatically capture and transmit weight data directly into logistics platforms. Studies cited by the WCO suggest that such integration can cut errors by as much as 15%. This means faster, more accurate VGM declarations and less risk of non-compliance.

- AI-Powered Load Optimization: Artificial intelligence is revolutionizing load planning. AI algorithms can predict potential weight distribution issues before loading, optimize how cargo is placed within a container to stay within limits, and even suggest the most efficient transport routes based on real-time weight restrictions and road conditions. This proactive approach prevents problems before they occur.

- Blockchain Verification: Imagine an immutable, transparent record of your cargo’s weight, accessible to all parties in the supply chain. Blockchain technology can provide just that, creating verifiable weight records that improve transparency, reduce disputes, and streamline compliance checks.

- Predictive Analytics and Integrated Compliance Checkers: Digital platforms leverage predictive analytics to forecast potential weight issues and suggest preemptive solutions. Integrated compliance checkers automatically verify shipments against the latest weight regulations for specific routes and modes, providing an extra layer of assurance.

By embracing these technological advancements, we can ensure unparalleled accuracy in weight verification, significantly reduce risks, and improve the overall efficiency of your overweight cargo shipments. Understanding how heavy equipment transport systems are evolving is key to leveraging these tools; learn more at Understanding Heavy Equipment Transport Systems: A Comprehensive Overview.

4. Beyond the Standard Truck: Opening up Advanced Overweight Cargo Solutions

When your cargo tips the scales beyond standard limits, traditional shipping methods just won’t cut it. This is where specialized equipment and advanced logistics strategies come into play, offering robust overweight cargo solutions that ensure safety and compliance. We specialize in these complex moves, leveraging our expertise and specialized assets to handle even the most challenging shipments.

One of the most common challenges for overweight cargo, especially for road transport, is axle weight distribution. A standard truck chassis can only handle so much before exceeding legal limits or stressing the equipment dangerously. This is why we turn to specialized equipment:

- Tri-Axle Chassis: These chassis feature an additional axle, distributing the weight over a larger area and allowing for higher cargo capacities on US highways. For example, a 20′ container on a triaxle chassis can often carry several thousand pounds more cargo than one on a standard chassis.

- Quad-Axle Chassis: Taking it a step further, quad-axle chassis provide even greater weight distribution, allowing for the transport of exceptionally heavy loads. They can increase weight capacity by up to 15% in trucking, making them indispensable for certain overweight cargo solutions.

- Flat-Rack and Open-Top Containers: For cargo that is not only heavy but also oversized or irregularly shaped, standard dry containers are unsuitable. Flat-rack containers have no side walls or roof, allowing for loading from the top or sides. Open-top containers have a removable roof, ideal for tall items. These specialized containers, combined with expert lashing and securing, are crucial for safe transport. For instance, a machinery exporter saved 25% on fees and was 18% under budget by pre-splitting loads and using flat-rack containers for a 35-ton cargo shipment.

- Heavy-Lift Vessels: For international sea freight of extremely heavy or large project cargo, specialized heavy-lift vessels are often the answer. These ships are equipped with powerful onboard cranes, sometimes with combined capacities of hundreds of tons, allowing for efficient loading and unloading of high-tonnage or irregularly shaped cargo without relying solely on port infrastructure.

- Heavy-Duty Forklifts and Mobile Cranes: At terminals and warehouses, specialized heavy-duty forklifts (e.g., 35-ton capacity) and mobile cranes (e.g., with combined capacities up to 250 tons) are essential for safely handling and transloading overweight cargo. These heavy equipment costs can range from $500-$2,000, but they are critical investments in safety and efficiency.

Beyond equipment, meticulous route planning and permit acquisition are vital. We analyze routes to avoid weight-restricted bridges or roads and secure all necessary permits from state and local authorities well in advance. This proactive approach minimizes delays and ensures compliance. Our comprehensive approach to Oversized Cargo Heavy Haul Transport Solutions ensures every detail is managed.

Essential Equipment for Heavy Loads

Here’s a quick rundown of the essential equipment we deploy for robust overweight cargo solutions:

- Tri-axle Chassis: For distributing weight over three axles, crucial for heavier container loads on US roads.

- Quad-axle Chassis: Offers even greater weight distribution, enabling the transport of super-heavy cargo.

- Flat-rack Containers: Ideal for cargo that is oversized or cannot be loaded through standard container doors.

- Open-top Containers: Perfect for tall items that exceed the height of a standard container.

- Heavy-duty Forklifts: For safe and efficient handling of heavy loads at ground level.

- Mobile Cranes: Essential for lifting and positioning extremely heavy or awkwardly shaped cargo.

For more details on how we manage and use this equipment, take a look at Handling OOG Equipment With Ease.

5. E-Commerce Has Its Own Playbook: Navigating Amazon FBA’s Weight Rules

E-commerce has reshaped global logistics, and with giants like Amazon leading the charge, even small parcels can contribute to significant weight considerations. If you’re shipping to Amazon’s Fulfillment By Amazon (FBA) centers, understanding their specific weight restrictions is non-negotiable. Amazon’s rules are designed to protect their employees, ensure efficient warehouse operations, and prevent equipment damage. Ignoring them leads to costly chargebacks, refusal of shipments, and processing delays.

Amazon’s shipping and routing requirements are quite detailed, and they’ve introduced some updates for 2026 that we need to be aware of. Previously, a standard carton limit was 50 lbs, but that has seen some changes.

Decoding Amazon’s 2026 Rules for Overweight Cargo Solutions

Here’s what we need to know for Amazon FBA in 2026:

- Standard Carton Limits: For most products, standard cartons are now allowed up to 60 lbs. This is a slight increase from previous years, offering a bit more flexibility for denser products.

- “Team Lift” Labels: If a carton weighs more than 50 lbs (even if it’s within the new 60 lb limit), it still requires a clear “Team Lift” label affixed to the top and sides. This alerts warehouse staff that two people are needed to safely move the package.

- “Mech Lift” Labels: For cartons that are exceptionally heavy, exceeding 100 lbs, a “Mech Lift” label is mandatory. This signals that mechanical equipment, like a forklift, is required for safe handling.

- New ‘Ultra-Heavy’ Category: Amazon has introduced a new ‘Ultra-Heavy’ category for cartons handling items from 100-150 lbs. While this provides a specific classification for heavier items, the “Mech Lift” label is still critical for these.

- Pallet Requirements: While cartons have their limits, pallets themselves also have specific dimensions and weight restrictions. Always ensure that your palletized shipments comply with Amazon’s guidelines for height, weight, and stability.

Understanding and adhering to these rules is a critical component of successful overweight cargo solutions for e-commerce. Non-compliance can lead to unexpected fees, shipment rejections, and delays that can severely impact your sales and inventory. For a deeper dive into Amazon’s specific requirements, consult their official Amazon’s shipping and routing requirements. Managing these details is part of our comprehensive Project Cargo Logistics services, ensuring your e-commerce shipments arrive without a hitch.

Frequently Asked Questions about Overweight Cargo

We often get asked similar questions about the complexities of shipping overweight cargo. Here are some of the most common ones, along with our expert insights.

What are the main consequences of non-compliance with overweight regulations?

The consequences of non-compliance are multifaceted and severe, impacting safety, finances, and legal standing.

- Safety Risks: Overweight containers can lead to vessels being improperly stowed, affecting ship stability and potentially causing containers to be lost overboard. On land, they can damage chassis, terminal handling equipment, and pose a significant risk of injury to dock workers. They also contribute to citations or accidents on highways and railways.

- Severe Fines and Penalties: Fines for overweight cargo can reach up to $10,000 per violation in key markets. Shipping lines often impose their own fines on shippers, and local authorities can issue penalties.

- Criminal Charges: In cases of severe negligence leading to accidents, shippers and carriers could face criminal charges.

- Shipment Seizure: Authorities have the right to seize overweight shipments until they are brought into compliance.

- Costly Delays: Overweight shipments often face delays ranging from 7-14 days as they are held for re-weighing, transloading, or obtaining special permits. This leads to additional costs like detention/demurrage fees (around $150 per day) and transloading fees ($1,000-$5,000).

- Surcharges: Expect overweight surcharges averaging 20-50% extra on freight rates.

What documentation is essential for shipping overweight cargo?

Accurate and complete documentation is critical for smooth and compliant overweight cargo shipments.

- Verified Gross Mass (VGM) Certificate: Mandated by SOLAS for sea freight, this document declares the accurate total weight of the packed container. The shipper is responsible for providing it.

- Bill of Lading (BOL): This legal document serves as a contract between the shipper and the carrier, detailing the type, quantity, and destination of the goods. It must accurately reflect the cargo’s weight.

- Special Permits for Road Transport: For overweight or oversized loads on highways, specific permits are required from state and local authorities. These permits often dictate routes, travel times, and escort requirements.

- Detailed Packing List: Provides a breakdown of all items within the shipment, their individual weights, and how they are packed.

- Cargo Insurance Documents: Always advisable for high-value and complex shipments to protect against loss or damage.

What is the best transport mode for very heavy cargo?

The “best” mode depends on the specific characteristics of your cargo, origin, and destination, but generally:

- Sea Freight: For very heavy cargo, especially volumes over 20 tons, sea freight is typically the most suitable and cost-effective option for long distances. Specialized heavy-lift vessels are designed to transport exceptionally heavy and oversized items, often equipped with powerful onboard cranes.

- Rail: For inland transport, rail can handle significantly heavier loads than road transport, particularly with the introduction of new high-capacity rail cars that can manage up to 50,000 lbs for a 20′ container in 2026. It’s an excellent choice for connecting major ports like Newark, NJ, and Savannah, GA, to interior destinations.

- Road (Specialized): While standard road transport has lower weight limits, specialized heavy haul trucking with multi-axle trailers (tri-axle, quad-axle) and expert route planning can handle substantial weights for shorter distances or the final leg of a journey.

Choosing the right mode, or combination of modes, requires careful planning and expertise to balance cost, transit time, and compliance. For comprehensive solutions, especially for heavy goods, refer to our Heavy Goods Transport Services: Oversized Cargo Shipping From The USA.

Conclusion: Turn Complexity into Certainty with the Right Partner

Shipping overweight cargo doesn’t have to be a headache. As we’ve explored, overweight cargo solutions is complex, with evolving regulations, significant financial implications, and the need for specialized equipment and meticulous documentation. From decoding 2026’s updated weight limits across different modes to mastering VGM requirements, leveraging tech-driven accuracy, deploying specialized equipment, and navigating Amazon FBA’s unique rules, each aspect demands expert attention.

The key to success lies in proactive planning and partnering with a logistics provider that brings not just experience, but also the in-house capabilities and dedicated presence needed for full control and reliability. At TRT International, we pride ourselves on managing all processes in-house, from initial planning to final delivery, ensuring seamless coordination and reducing risks. Our multilingual agents and strategic port zone offices in locations like Newark, NJ, and Savannah, GA, mean we are always close to the action, ready to handle your most challenging shipments.

Don’t let the complexities of overweight cargo slow down your business or lead to unforeseen costs. Turn complexity into certainty by working with a partner who understands the nuances and has the proven solutions.

Explore our comprehensive bonded warehouse and logistics services and let us help you steer your next overweight cargo challenge with confidence.