Why Heavy Equipment Transport Is Critical for Your Business

Heavy equipment transport is the specialized process of moving machinery and vehicles that weigh 10,000 pounds or more, requiring expert handling, specialized trailers, permits, and meticulous planning to ensure safe delivery.

Key aspects of heavy equipment transport:

- Definition: Transport of vehicles weighing 4,536 kg (10,000 lbs.) or more, including construction, agricultural, and industrial machinery

- Specialized Requirements: Oversize/overweight permits, specialized trailers (flatbed, step-deck, RGN, lowboy), and experienced carriers

- Regulations: FMCSA cargo securement rules, federal weight/dimension limits (102" width, 80,000 lbs gross weight), and state-specific permits

- Cost Factors: Distance, weight/dimensions, permits, escort vehicles, fuel surcharges, and timeline

- Safety Considerations: Proper securing with minimum four tiedowns, trained operators for loading/unloading, route planning, and escort vehicles for oversized loads

Moving massive machinery like bulldozers and cranes is more than just a big truck ride. It's a complex logistical operation that demands precision, expertise, and careful coordination. From understanding federal regulations to selecting the right trailer type, heavy equipment transport involves multiple moving parts that can make or break your project timeline.

The stakes are high. Construction machinery was the leading cause of fatal collisions from 1992 to 2010, and 48.7% of delivery drivers are injured during loading and unloading operations. These statistics underscore why choosing the right transport partner isn't just about cost—it's about safety, reliability, and regulatory compliance.

Whether you're shipping excavators across state lines or moving industrial equipment internationally, this guide walks you through everything you need to know: what qualifies as heavy equipment, the regulatory landscape, trailer selection, route planning, and how to choose a transport partner you can trust.

What Constitutes "Heavy Equipment"?

When we talk about heavy equipment transport, what exactly are we referring to? It’s more than just a large machine; it's any vehicle or machinery designed for heavy-duty tasks across various industries. The Federal Motor Carrier Safety Administration (FMCSA) provides a clear definition: heavy equipment refers to vehicles operating on wheels or tracks, such as front-end loaders, bulldozers, tractors, and power shovels, that individually weigh 4,536 kg (10,000 lbs.) or more. This weight threshold is a critical factor in determining the specialized transport requirements.

Our expertise spans a wide array of machinery, including both wheeled and tracked equipment, each presenting its own unique transport considerations.

Here’s a list of common heavy equipment types we regularly handle:

- Excavators: Used for digging, demolition, and heavy lifting. Their large size and tracks often require specialized trailers.

- Bulldozers: Powerful machines for pushing soil and debris, often tracked, demanding robust transport solutions.

- Cranes: From mobile cranes to large tower crane components, these require careful disassembly and specialized hauling.

- Tractors: Essential in agriculture, varying greatly in size and weight, from smaller utility models to massive farm tractors.

- Combines: Large harvesting machines, often oversized in width and height, crucial for farm equipment transport.

- Forklifts: While some are smaller, heavy-duty industrial forklifts easily exceed the 10,000-pound threshold.

- Loaders: Wheel loaders and skid steers are common in construction and agriculture, often requiring specific securement.

The United States is a global leader in the manufacturing of construction machinery, with companies like Caterpillar and John Deere collectively contributing to 21.7% of the global construction equipment market revenue. This robust industry means a constant need for efficient and safe heavy equipment transport.

The transport needs for different types of heavy equipment are highly differentiated:

- Construction Equipment: This category includes everything from excavators and bulldozers to graders and pavers. They often have irregular shapes, tracks instead of wheels, and significant weight, necessitating specialized trailers like lowboys or RGNs.

- Farm Machinery: Tractors, combines, planters, and tillage equipment are frequently oversized, especially in width, requiring careful route planning and permits.

- Industrial Machinery: This can range from large factory components to power generators, often custom-built and requiring bespoke transport solutions.

Understanding the specific characteristics of each piece of equipment—its dimensions, weight, and any unique features—is the first step in planning a successful heavy equipment transport.

The High Stakes of Heavy Hauling: Core Challenges and Safety

Transporting heavy equipment is far from a simple task. It involves inherent complexities and risks that demand meticulous planning and execution. The primary challenges we face include:

- Extreme Weight: Moving items that weigh tens or even hundreds of thousands of pounds puts immense stress on roads, bridges, and transport vehicles, requiring specialized trailers and careful weight distribution.

- Oversized Dimensions: Many pieces of heavy equipment exceed standard legal width, height, and length limits, leading to the need for special permits, route planning, and often escort vehicles.

- Logistical Complexity: Coordinating permits across multiple states, managing loading and unloading, route surveys, and adhering to strict timelines all contribute to the intricate nature of heavy equipment hauling.

Safety is paramount in our industry, and for good reason. The statistics are sobering:

- Construction machinery was the leading cause of fatal collisions from 1992 to 2010. This highlights the critical need for professional and compliant transport.

- A significant portion of incidents occurs during the most vulnerable phases: loading and unloading. It’s estimated that 48.7% of delivery drivers are injured during loading and unloading, whereas only 28.7% of operators reported incidents. Insecure load incidents were primarily due to canopies detaching or machines falling off ramps.

These figures emphasize that safe heavy equipment transport isn't just about the journey; it's about every step, from preparation to final delivery.

Loading and Unloading Best Practices

To mitigate these risks, we adhere to strict best practices for loading and unloading:

- Trained Operators: Only certified and experienced operators should handle the equipment during loading and unloading.

- Level Ground: Operations must always take place on stable, level ground to prevent tipping or shifting.

- Proper Ramps: Using appropriate ramps designed for the equipment's weight and dimensions is crucial.

- Clear Communication: Constant communication between the equipment operator, truck driver, and ground crew ensures everyone is aware of movements and potential hazards.

Mitigating Risks

Beyond operational best practices, we employ several strategies to mitigate the inherent risks of heavy equipment transport:

- Thorough Planning: Every move begins with exhaustive planning, including detailed route surveys, permit acquisition, and contingency planning.

- Vetting Transport Partners: We ensure that all partners in our network are experienced, reputable, and fully compliant with all regulations.

- Comprehensive Insurance: Adequate insurance coverage for the equipment and the transport process is non-negotiable.

We go above and beyond to provide a top-quality shipping experience for every client, ensuring that your valuable assets arrive safely and on schedule. Our commitment to safety is reflected in our robust solutions for oversized cargo. For more details on how we prioritize safety and efficiency, please explore our safety-focused solutions.

The Right Tools for the Job: Trailers and Transport Methods

Choosing the correct trailer is fundamental to successful heavy equipment transport. Just as a chef needs the right knife, we need the right trailer to ensure the safe and efficient movement of your valuable machinery. The type of equipment, its dimensions, and weight dictate the appropriate trailer.

Here’s a comparison of the most common trailer types used in heavy hauling:

| Trailer Type | Typical Max Weight (approx.) | Typical Max Height (on trailer) | Best For |

|---|---|---|---|

| Flatbed Trailer | 48,000 lbs | 8.5 - 9 ft | Smaller equipment, materials, items that can be loaded from top or side. Good for forklifts, smaller excavators, pipes, lumber. |

| Step-Deck Trailer | 48,000 lbs | 10 - 10.5 ft | Taller equipment that exceeds flatbed height limits but doesn't require a lowboy. Often used for tractors, medium-sized excavators, and construction equipment. |

| Double Drop Trailer | 42,000 lbs | 11.5 - 12 ft | Very tall equipment, with a "well" in the middle to provide extra vertical clearance. Ideal for large machinery that must stay within height restrictions. |

| Removable Gooseneck (RGN) Trailer | 42,000 - 150,000+ lbs | 11.5 - 12 ft | Heaviest and tallest equipment. The front detaches, allowing equipment to be driven onto the deck, making it perfect for excavators, bulldozers, and large industrial components. |

Domestic Trailer Types for Heavy Hauls

- Flatbed Trailers: These are the most versatile and common trailers, suitable for smaller construction equipment and materials that can be loaded from the top, back, or sides. Examples include smaller forklifts, backhoe loaders, skid steers, and structural components.

- Step-Deck Trailers: Also known as drop-deck trailers, these feature a lower deck in the middle, allowing us to transport taller equipment that would exceed legal height limits on a standard flatbed. They are ideal for medium-sized excavators, tractors, and other construction machinery.

- Double Drop Trailers: These go a step further than step-decks, featuring an even lower "well" in the middle, making them perfect for exceptionally tall equipment. The lower center of gravity also improves stability.

- Removable Gooseneck (RGN) Trailers: These are the champions of heavy equipment transport for the largest and heaviest loads. The front section (gooseneck) detaches, creating a ramp that allows equipment to be driven directly onto the trailer's main deck. This "drive-on" capability is invaluable for tracked vehicles like excavators and bulldozers, providing a safe and efficient loading process. RGNs can also be configured with multiple axles for super heavy loads.

International Heavy Equipment Transport Options

When your equipment needs to cross oceans, we use specialized international shipping methods:

- Roll-On/Roll-Off (Ro-Ro) Shipping: This method is perfect for wheeled or self-propelled equipment. Your machinery is simply driven onto a purpose-built vessel at the port of origin and driven off at the destination port. It’s efficient, reduces handling, and minimizes the risk of damage.

- Flat-Rack Containers: For non-wheeled or irregularly shaped oversized equipment, flat-rack containers are an excellent solution. These are essentially shipping containers without side walls or a roof, allowing us to secure oversized items directly onto the base. They can then be stacked and shipped like standard containers.

We pride ourselves on handling out-of-gauge (OOG) equipment with ease, ensuring that even the most challenging international shipments are managed expertly. Learn more about our capabilities in handling OOG equipment with ease.

While our focus is primarily on civilian and commercial transport, it's worth noting that specialized military transport systems, like the Heavy Equipment Transporter System (HETS), exist for moving tanks and other heavy military vehicles, showcasing the extreme end of specialized transport.

Navigating the Legal Labyrinth of Heavy Equipment Transport

Understanding and complying with the myriad of regulations is arguably the most critical aspect of heavy equipment transport. Failure to do so can result in significant delays, hefty fines, and even safety hazards. We operate under stringent federal guidelines, primarily those set by the Federal Motor Carrier Safety Administration (FMCSA).

FMCSA Regulations

The FMCSA establishes comprehensive rules to ensure the safe transportation of cargo, particularly heavy equipment:

- Cargo Securement Rules: Under 49 CFR 393.130, the FMCSA provides specific guidelines for securing heavy machinery. This includes requirements for accessory equipment (like buckets or booms) to be lowered and secured, and articulated vehicles to be restrained from articulating. Most importantly, heavy equipment with crawler tracks or wheels must be restrained against movement in the lateral, forward, rearward, and vertical directions using a minimum of four tiedowns. Each tiedown must be affixed as close as practicable to the front and rear of the vehicle or to specifically designed mounting points. These are universal cargo securement rules we strictly follow.

Oversize and Overweight Loads

Like all commercial trucks, vehicles transporting heavy machinery are subject to federal width, length, and size limits on the National System of Interstate and Defense Highways.

- Federal Limits: The maximum width limitation is 102 inches (8.5 feet). Federal maximum weights include 80,000 pounds gross vehicle weight, 20,000 pounds single axle weight, and 34,000 pounds tandem axle weight.

- State-Level Permits: When your equipment exceeds these federal limits, it's classified as an "oversize" or "overweight" load. Transporting such loads requires special permits issued by each state the shipment will pass through. The permitting process involves detailed applications, route planning, and adherence to state-specific regulations regarding travel times, speed, and escort vehicle requirements. Given our locations in Newark, NJ, and Savannah, GA, we are highly experienced in navigating the permitting processes for these states and neighboring regions.

Super Loads

Sometimes, equipment is so exceptionally large or heavy that it exceeds even the standard oversize and overweight specifications. These are known as "Super Loads."

- Definition: Super loads are typically defined as loads that surpass a state's maximum legal dimensions or weight even with standard oversize permits. They require extra special consideration, including highly detailed route planning, structural analysis of bridges, and dedicated permits that can take weeks or even months to secure.

- State-Specific Rules: The exact specifications for super loads vary significantly from state to state. For example, some states classify loads greater than 15′-0″ wide, 17′-0″ high, and 135′-0″ long as super loads. This necessitates a deep understanding of each state’s specific requirements.

The Role of Escort Vehicles (Pilot Cars)

For many oversize and super loads, escort vehicles, often called pilot cars, are not just helpful; they are legally mandated.

- When They Are Required: Regulations regarding pilot cars vary by state and depend on the dimensions of the load (e.g., width, length, height). Generally, once a load exceeds a certain width or length, one or more pilot cars (front, rear, or both) are required to accompany the transport vehicle.

- Safety Functions: Pilot cars play a crucial role in enhancing safety by:

- Warning oncoming traffic of the oversized load.

- Guiding the truck through turns and challenging road sections.

- Assisting with lane changes and temporary road closures.

- Ensuring route clearances and managing traffic flow around the load.

Navigating these complex regulations requires expertise and experience. We specialize in managing all aspects of oversize transportation, ensuring full compliance and smooth transit for your valuable equipment. Learn more about our Oversize Transportation Services.

Strategic Planning: Your Blueprint for a Successful Move

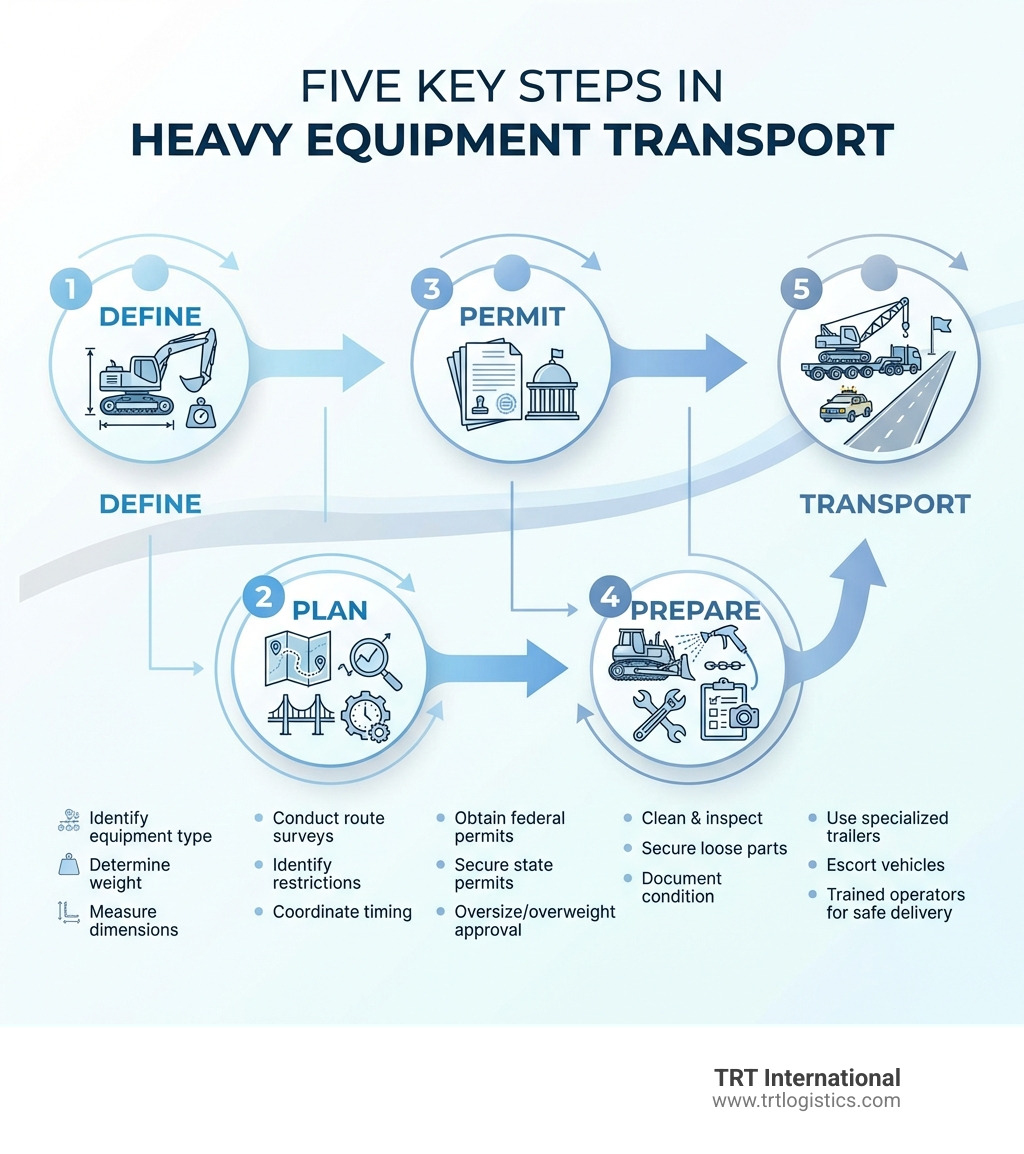

The success of any heavy equipment transport hinges on meticulous strategic planning. We don't just put your equipment on a truck; we engineer a comprehensive solution that anticipates every challenge.

The Importance of Route Planning

Route planning for heavy equipment is a sophisticated process that goes far beyond simply plugging addresses into a GPS. We conduct thorough route surveys to identify potential obstacles and ensure a clear path for your oversized cargo:

- Identifying Bottlenecks: This involves pinpointing narrow roads, tight turns, or congested urban areas that could impede progress.

- Bridge Clearances and Weight Limits: We carefully check bridge heights and weight capacities along the entire route. An overlooked bridge could lead to catastrophic delays or structural damage.

- Road Weight Limits: Beyond bridges, local roads often have specific weight restrictions, especially during certain seasons (e.g., thaw laws). Our planning accounts for these to prevent unexpected detours or fines.

- Route Surveys: For super loads or particularly complex routes, we might physically survey the path, sometimes even driving it ourselves, to identify any unforeseen issues. This proactive approach minimizes surprises during transit.

Preparing Your Heavy Equipment for Transport

Proper preparation of your equipment is vital for safety and to prevent damage. Think of it as preparing for a long journey – a little foresight goes a long way:

- Cleaning and Inspection: We recommend giving the machinery a good cleaning. This allows for a thorough inspection, where we can document its condition with pictures and videos. This documentation is crucial for insurance purposes and provides a baseline for its condition pre-transport.

- Securing Loose Parts: Any detachable or movable parts, such as buckets, booms, hydraulic cylinders, or even small tools, must be lowered, retracted, and securely fastened. Accessory equipment should be lowered and secured, and articulated vehicles must be restrained from articulating. This prevents movement and potential damage during transit.

- Disconnecting Batteries: For long-distance transport, especially if the equipment won't be operated for a while, disconnecting the battery can be a wise precaution to prevent drainage or electrical issues.

Cost Factors and Choosing a Partner

The cost of heavy equipment transport is influenced by several variables, and understanding them is key to getting accurate quotes:

- Distance: Longer distances naturally incur higher fuel, labor, and permit costs.

- Dimensions & Weight: The larger and heavier your equipment, the more specialized the trailer, permits, and potentially escort vehicles required, all of which add to the cost.

- Permits: Each state requires permits for oversize/overweight loads, and their cost varies. Super load permits are significantly more expensive and complex.

- Escort Vehicles: When required, pilot cars add to the overall expense, as they involve additional personnel and vehicles.

- Fuel Surcharges: Fluctuations in fuel prices can impact the final cost, often accounted for through fuel surcharges.

Choosing a reliable partner is as important as the equipment itself. We recommend looking for:

- Experience Verification: A proven track record in heavy equipment transport, especially with similar types of machinery and routes.

- Insurance Coverage: Comprehensive cargo insurance is non-negotiable. Ensure your partner carries sufficient coverage for your equipment's value.

- In-house Logistics Management: Our unique selling proposition at TRT International is managing all processes in-house. This means we have full control and reliability over every step of your shipment, from planning and permitting to execution and tracking. This integrated approach, supported by multilingual agents and our port zone office, streamlines communication and problem-solving, offering you peace of mind.

For more insights into how to steer the complexities of oversized freight and choose the right partner, check out our guide on Navigating Oversized Freight.

Scheduling and Logistics

Effective scheduling and logistics are critical to avoiding costly delays and ensuring projects stay on track:

- Allowing Ample Time: Rush jobs for heavy equipment transport can lead to higher costs, potential accidents, or damage. We always recommend leaving a generous window for planning, permitting, and execution.

- Coordinating with Sites: Close coordination with both pickup and delivery sites is essential. This includes ensuring site readiness, access for large transport vehicles, and availability of personnel for loading/unloading.

- Flexibility for Delays: Despite the best planning, unforeseen circumstances like weather, road closures, or permit delays can occur. Building flexibility into the schedule is a best practice.

Conclusion: Partnering for a Smooth and Secure Transport

As we’ve explored, heavy equipment transport is a highly specialized field fraught with complexities. From the sheer weight and dimensions of the machinery to the intricate web of federal and state regulations, every aspect demands expert attention. We've seen that safety is not just a buzzword but a critical operational imperative, underscored by sobering statistics on accidents during transport and loading. Meticulous planning, including detailed route surveys and equipment preparation, is the bedrock of a successful move.

The value of expertise in this domain cannot be overstated. Engaging with a professional partner who understands the nuances of trailer types, permitting processes, and risk mitigation strategies is not merely a convenience; it's a necessity for safeguarding your assets, maintaining project timelines, and ensuring regulatory compliance.

At TRT International, we pride ourselves on being that trusted partner. Our commitment to managing all processes in-house provides you with full control and reliability, from the initial quote to final delivery. Our team of multilingual agents and our strategic port zone office in Newark, NJ, and Savannah, GA, enable us to offer seamless, end-to-end solutions for even the most challenging heavy equipment transport needs. We are dedicated to delivering a quality shipping experience that removes the guesswork from heavy hauling.

Don't let the complexities of heavy equipment transport become a burden. Partner with us for a smooth, secure, and expertly managed move. Get expert help with your Heavy Goods Transport Services today, and let us handle the heavy lifting.